Bio-hydrox has been proved effective at treating produced water, bringing solutions to difficult situations where the highest level and very effective oxidation is required, and where biocide reliability is not questionable.

◘ It eliminates all aerobic and anaerobic bacteria in a few seconds.

◘ It removes biofilm from the pipes and prevent pitting, erosion and scaling.

◘ It nullifies hydrogen sulfide in liquid and gas phases.

◘ Bio-hydrox is a demulsifier, water clarifier and corrosion inhibitor. It will make all your chemicals work more efficiently and you may require less amount of them to obtain same results.

◘ Bio-hydrox will change the surface structure of the paraffins and asphaltenes preventing crystalization. Your crude will be thinner and flow better which translate in higher productivity.

CASE STUDY I: STRIPPER WELLS GO FROM 1 BBL TO 15 BBL PER DAY!

Pecos County,TX. We ran a study on 4 stripper wells with 1 to 2 bbl per day production. 5 gal of Bio-hydrox were injected daily into each casing. Production increased to 15 BBL every 12 hours of operation. H2S was eliminated in the gas and liquid phase. Bio-hydrox changed the surface structure of paraffin/asphaltenes so that it would not form a deposit. The results of the produced water showed no detectable levels of iron, bacteria and H2S. It is estimated more than 50% of the oil beneath stripper wells cannot be removed because of low pressure, permeability and paraffin.

As the fields begin to produce oil at the wellbore, the pressure drops and slows production. With the heat entering the wellbore there is also a loss due to permeability. The oil begins to cross its cloud point threshold, and paraffin crystals precipitate and create thick deposits as the oil moves to the wellbore opening. Biofilm buildups helps paraffin to deposit. Bio-hydrox advanced oxidation technology quickly reacts with hydrogen and iron sulfide, destroys biofilm and kills bacteria. It is also effective as an emulsion breaker and micro-flocculent in the treatment of produced water.”

https://www.linkedin.com/feed/update/urn:li:activity:6417603610317848576

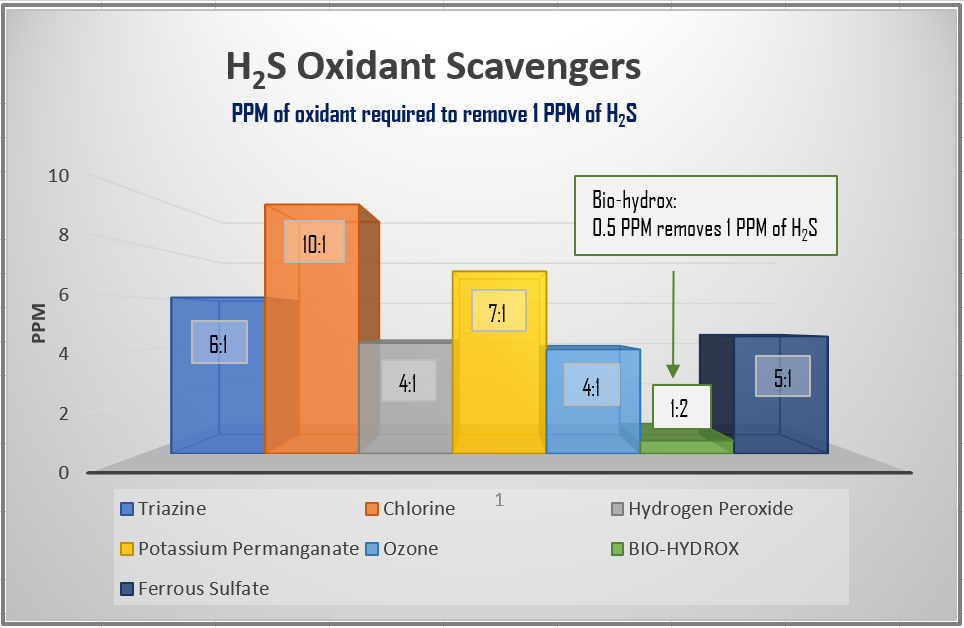

CASE STUDY II: REMOVAL OF H2S GAS SCRUBBER APPLICATION

In a recent bench study in Houston, TX, H2S was removed from a natural gas stream containing 2,000 mg/L of H2S and 5% CO2 using a 3% solution of Bio-hydrox , a mineral oxychloride oxidation catalyst with effective ROS regeneration and high yield production of hydroxyl radicals. The operating conditions of a wet scrubber were simulated by blowing the gases thru a container with the 3% solution of Bio-hydrox. H2S was bubbled at a rate of 2,000 ppm each minute. It was found the radicals quickly took the ORP from -150 mV to +100 mV and completely eliminated the H2S at a 1:2 ratio (1 PPM of Bio-hydrox removed 2 PPM of H2S). The residuals were inert sulfate compounds.

The contact time for H2S to react is inversely proportional to the oxidation potential of the oxidizer. Bio-hydrox oxidation potential is 2.8 to 2.9 V and is so fast reacting that there is no reversion back to H2S or form precipitants. Bio-hydrox is also very effective at eliminating SOx, CO2, NOx and preventing greenhouse emissions.

Bio-hydrox is cost-effective, non-toxic and meets EPA Green Chemistry standards.

https://www.linkedin.com/feed/update/urn:li:activity:6423641888124997632

https://www.linkedin.com/feed/update/urn:li:activity:6439334118449909760