Wondering how to reduce TOC? How to oxidize organic load? How to lower THMs? HAA5?

How to reduce disinfection by-products? How to maintain chlorine residual? How to control biofilm?

The mineral oxychloride solution is the first advanced oxidation liquid chemical certified EPA FIFRA 3(c)(5) as antimicrobial pesticide and NSF/ANSI 60 as a drinking water treatment product. Bio-hydrox can be an alternate to chlorinated chemicals, Peracetic Acid, Hydrogen Peroxide, all oxidant and non-oxidant biocides, and other treatments like ozonation, ionization and UV radiation, providing long residual protection, no resistant microorganism and no toxic by-products.

Up until now, advanced oxidation had been almost exclusively a treatment option for industrial effluents and challenging situations due to the cost, blueprint and complicated application. Bio-hydrox can be less expensive than chlorine and sodium hypochlorite; often less expensive than chloramines and chlorine dioxide, and for the most part less expensive than peracetic acid, hydrogen peroxide and the rest of the biocides used in the industry.

Other advantage of Bio-hydrox is storage. It is very stable in normal storage conditions with a conservative shelf life of at least 6 months and will take much less space than chlorinated products since it could require 15 to 20 times less volume to achieve same results. The concentration and quality control are measured with an ORP meter. Other easy to use, off label field tools that work with Bio-hydrox are OTO chlorine test, chlorine meters and chlorine strips, as well as hydrogen peroxide strips. None compare to the accuracy of ORP meters and the indicators will not be consistent with the intendent oxidant scale, however, they can come handy and will do the job in many applications.

- Financially suitable and scalable to municipal WTP and large operations.

- Can be more economic than chlorinated chemicals.

- More reactive than Chlorine and can kill bacteria and virus on contact.

- Implementation without the need of capital investment.

- No ongoing energy consumption.

- Works well with all water treatment chemicals and can be used without a transition period.

- Can be retrofitted to lower energy consumption, extend life and improve performance of existing ozone generators and UV radiation.

- Easiest to implement and the most effective advanced oxidation process.

- Longest residual activity of all water treatment products in the market.

- Negligible impact to footprint (all you need is a dosing pump!).

- Destroys biofilm.

- As a biocide, there is not known microorganism that can survive the oxidative stress of advanced oxidation technology.

- Best at odor and color removal.

- Very potent in oxidization of organic/inorganic pollutants.

- Promising mineralization of stable, inhibitory, toxic contaminants with low biodegradability.

- Degradation of recalcitrant compounds.

No matter what your challenge is, we can help your facility will never be in violation.

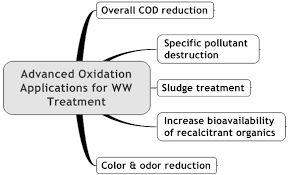

Bio-hydrox is a wide spectrum biocide. E. Coli, Cryptosporidium and Giardia cannot build resistance against oxidative stress. There is not known microorganism that can survive advance oxidation. It is a viable option in any industry and application that needs an effective biocide and oxidant, without generating toxic by-products. In the case of water treatment plants, when Bio-hydrox is used, it will (not an all-inclusive list):

- Kill all pathogens

- Oxidize emerging and environmental pollutants

- Degrade recalcitrant compounds and mineralize contaminants

- Noticeable improve the clarity of the water

- Significantly reduce the organic load and the oxygen demand

- Destroy biofilm and control algae growth

- Aid flocculation and precipitate suspended and dissolved solids, including heavy metals

- Oxidize ammonia and optimize the nitrification process

- Completely eliminate odor

- Improve the flavor of the drinking water

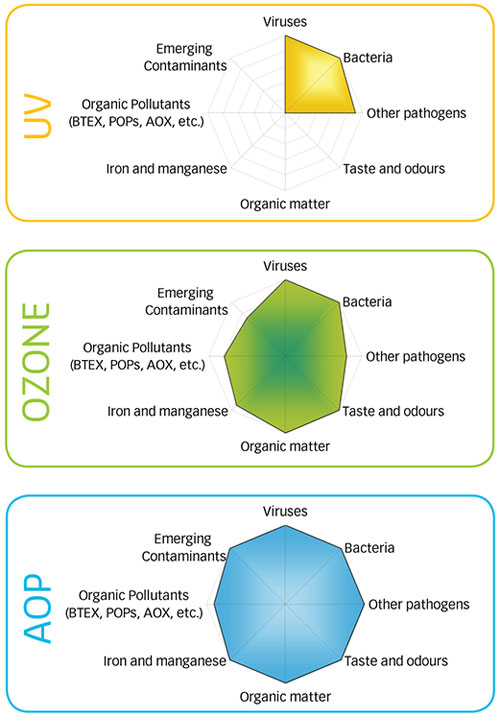

If you are already familiar with ozonation it is very easy to understand why Bio-hydrox is superior to all water treatment oxidants and disinfectants, will improve your overall treatment process and significantly lower your operational expenses.

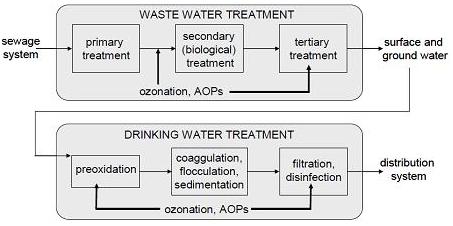

There are two main defining differences between the traditional ozonation process as supposed to using liquid Ozone:

- First, the way it is produced and introduced in the water. Ozone gas is produced on site by an Ozone generator or UV light and incorporated into the water in a gas phase with low solubility, mixing in the form of a heterogeneous chemical reaction between a gas and a liquid. It needs a big capital investment and complex operation which includes an Ozone destructor to control toxic levels of the undissolved gas that escape into the environment. On the other hand, liquid Ozone does not require upfront capital investment and is manufactured at a licensed facility. It is incorporated into the water in a liquid phase where it releases a more soluble oxidizing agent and mixes in the form of a homogeneous and most effective chemical reaction. Bio-hydrox has 100% solubility and there is no gas escaping the water.

- Second is the oxidizing agent. Ozone gas follows a pathway that directly oxidizes pollutants in one reaction of energized Oxygen ions. In alkaline and/or catalyzed environments, the oxidation process may follow a second pathway where Ozone gas creates other Oxygen ions and radicals and indirectly oxidizes pollutants with various reactions and better results. It happens a little different for liquid Ozone since it is not sensitive to pH and does not require external catalysts. Liquid Ozone generates a cascade of ROS in a redox cycle perpetuated by the metal catalysts in solution with high yield production of Hydroxyl radicals, which oxidize contaminants with a synergistic effect and an estimated oxidation potential between 2.8 V to 2.9 V, higher than Hydroxyl radicals acting alone.

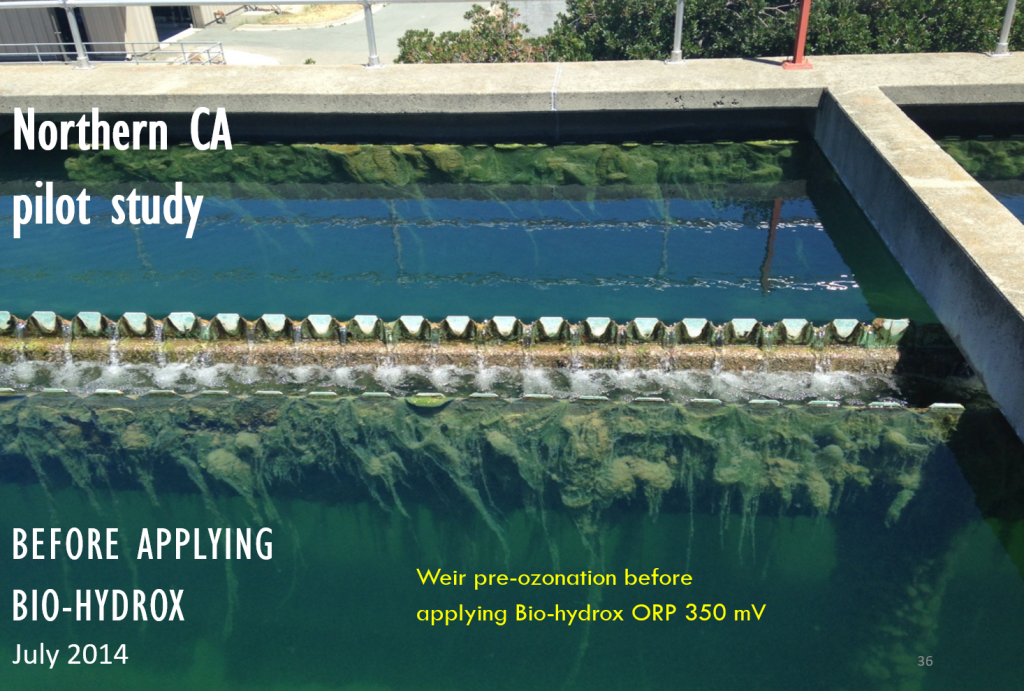

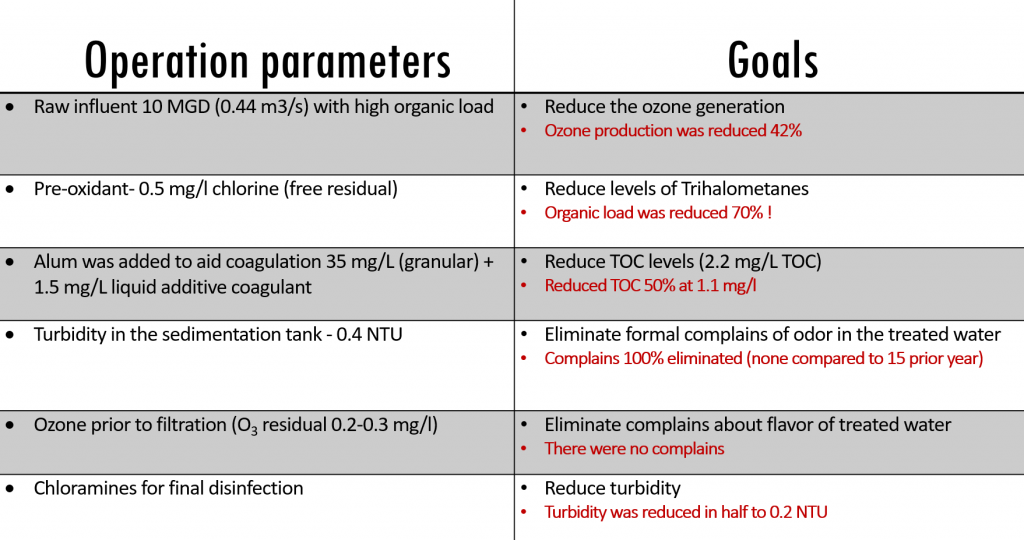

Case study: Pre-oxidation for the control of Filamentous algae, taste and odour