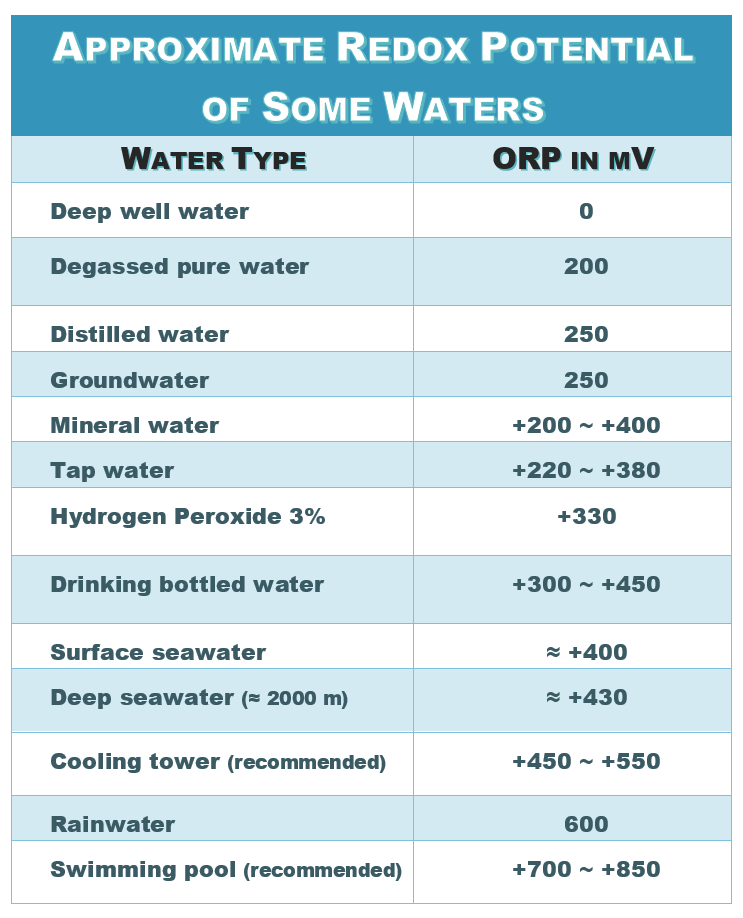

Oxidation reduction potential, also called redox or ORP, is the energy potential for chemical processes to neutralize contamination. The ORP level shows the minimal voltage in the water, which comes from the electric charge of reducing agents or oxidizing agents. An ORP meter measures in millivolts, or mV.

As the concentration of molecular oxygen increases, the redox potential increases: An increase of dissolved molecular oxygen from 0.5 to 1.5 mg ˣ L-1 (1 ppm) is accompanied by an increase in redox potential of 7 mV.

As the concentration of molecular oxygen decreases, the redox potential decreases: A decrease of dissolved molecular oxygen from 1.5 to 0.5 mg ˣ L-1 (1 ppm) is accompanied by a decrease in redox potential of 7 mV.

As the concentration of molecular hydrogen increases, the redox potential decreases: An increase of dissolved molecular hydrogen from 0.5 to 1.5 mg ˣ L-1 (1 ppm) is accompanied by a decrease in redox potential of 14 mV.

As the concentration of molecular hydrogen decreases, the redox potential increases. An increase of dissolved molecular hydrogen from 0.5 to 1.5 mg ˣ L-1 (1 ppm) is accompanied by a decrease in redox potential of 14 mV.

As the concentration of hydrogen ions increases (and pH decreases), the redox potential increases: A decrease of one pH unit (10 ˣ more acidic) is accompanied by an increase in redox potential of 59 mV at 25 °C.

As the concentration of hydrogen ions decreases (and pH increases), the redox potential decreases. An increase of one pH unit (10 ˣ more alkaline) is accompanied by an decrease in redox potential of 59 mV at 25 °C.

Small changes in the hydrogen ion concentration (pH) can cover up large changes in the hydrogen or oxygen concentrations.